- Arduino robotic arm how to#

- Arduino robotic arm serial#

- Arduino robotic arm full#

- Arduino robotic arm software#

- Arduino robotic arm code#

Arduino robotic arm code#

Now, upload the modified main code (sketch: code.ino) to arduino. Replace 0x00 with the new code in the below line: case 0x00: Serial.println(" *") rcv_char = 'F' break In effect, manually controlling a Robotic Arm. You can download. cheap SSG 90 servo motors that are powered by the Arduino board.

Arduino robotic arm full#

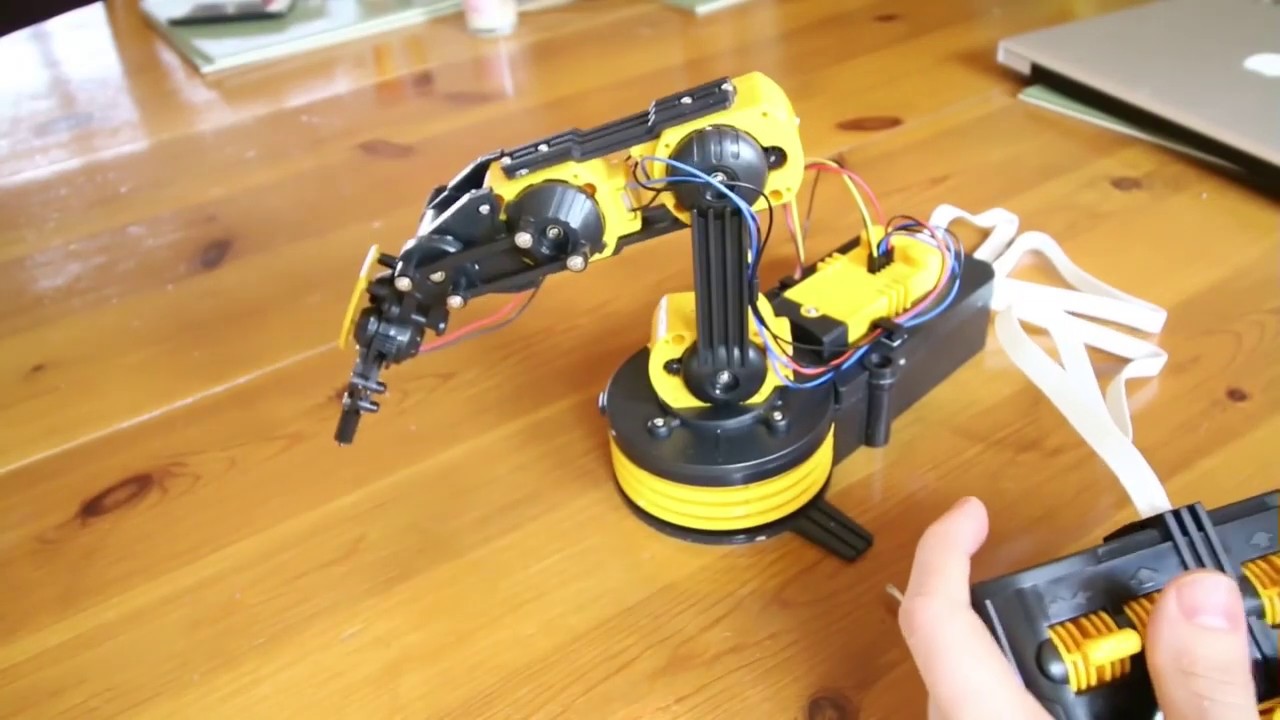

Advanced Full instructions provided 39,057 Things used in this project Story This project uses 4pcs.

Arduino robotic arm serial#

Next, press * button and get the hex code from serial monitor. A relatively easy to build and quite cheap robotic arm. Now open the main program (“ code.ino” sketch) and replace 0x00 in the line shown below: case 0x00: Serial.println(" -OK-") rcv_char = '!' break After the Arduino records the motions you taught it, the arm can replay the motion with the press of a button. Open the serial monitor in the arduino IDE and press OK button on the remote (any button that you wish to use for “start”/”stop”). Inspired by the Baxter robot and made possible with the Adafruit Analog Feedback Servos, this robotic arm can be trained to move around by simply manipulating it with your hands. (sketch: IRBUTTONS.ino)Ĭonnect the receiver pin on the IR sensor to pin 12 of arduino.

Arduino robotic arm how to#

This video is a tutorial on how to build a DIY Robotic Arm controlled by hand. To do this, upload the code for testing IR remote control. Contribute to EbenKouao/arduino-robot-arm development by creating an. The next evolution of the Tinkerkit Braccio robot, Arduino Braccio ++ is a robotic arm designed solely for higher education, including engineering schools and university institutes of technology or even advanced high school and college students studying the sciences, industrial science or technology. We will also be interfacing Arduino with an IR receiver to sense “save” and “start”/”stop” commands.įirst, We will need to get the key codes for our save and start/stop buttons. Just that, we will be using an ultra sound sensor to detect if an object is present in the pickup position, before the arm starts the sequence. Once training sequence is stored, we will be able to play the sequence over and over. It is possible to make the arm move to a position, pickup an object and place it in another location.Īfter moving each section of the arm, we will be pressing the save button on the IR remote to store the movement. While training the robotic arm, we will be controlling each section of the arm by adjusting respective potentiometers. Battery & 5v voltage regulator or a 5V power supply.A robotic arm kit | something like this : Amazon link Arduino IDE About this project This robotic arm is a easy one, and it can be made out of household materials.It can be trained to do a sequence of activity, and the arm will repeat the same sequence when played back. Now that we have seen the simple circuit diagram, we will jump to the actual construction. The controller is interfaced with a Bluetooth receiver that is used to. We will be making an automated robotic arm and hence we don’t require any potentiometers. The 6 Dof arm makes use of 6 servo motors controlled by an arduino Uno controller. The hardware is open-source, and comes with a digital content platform containing many more step-by-step lessons and projects.This time, I’ve made an arduino controlled robotic arm. The control pins of each servo must be connected to the PWM pins of the Arduino. It can be assembled in several different ways to facilitate different movements, including attaching a solar panel and tracking the movement of the sun. FIGURE 8 Robotic arm, embedded controller and companion computer. Inside, there are six Arduino RS485 Smart Servo Motors, four in the arm and two to control the claw.

All its plastic parts are 100% recyclable. of a RC servo motor back and forth across 180 degrees using Arduino IDE. The arm itself is made from recycled food cartons rather than virgin ABS plastic, with an aluminum layer for strength. Learn how to make your own DIY color sorting robotic arm using ultrasonic and. The Carrier also has IO headers to connect accessories. There's also a new version of the Braccio Carrier board, with a mini joystick and small LCD screen, to enhance custom projects.

Arduino robotic arm software#

It sticks to the usual Arduino Nano form factor, and has full support for the entire RP2040 software ecosystem, including MicroPython. ROS packages that can be used to plan and execute motion trajectories for a robot arm in simulation and real-life. The Nano Connect joins the usual RP2040 controller chip with 16MB of additional flash storage, a microphone and motion sensors, plus a u-blox NINA-W102 radio module which brings Wi-Fi and Bluetooth 4.2 to the board.

0 kommentar(er)

0 kommentar(er)